Air conditioner Fixing: Professional Cooling System Restoration Ensures Your Home Stays Comfy During The Hottest Days

Common Air Conditioning Problems

Have you ever felt that sudden rush of warm air just when you anticipated a cool breeze? It's frustrating, isn't it? Many homeowners face this issue, often unaware of what hides below the surface of their a/c system. Let's unravel the mystery behind some of the most regular concerns that demand timely cooling repair.

Why Won't My AC Cool Properly?

When your AC system blows lukewarm air rather of read more a rejuvenating chill, it's a clear sign something's off. A stopped up filter or low refrigerant levels often play the bad guy here. Imagine attempting to breathe through a headscarf on a hot day-- that's what a dirty filter does to your system. Ever questioned why your energy expenses surge when the cooling drops? That's your air conditioning struggling harder to make up for inadequacies.

Odd Noises and What They Mean

Clicking, buzzing, or rattling sounds aren't just sounds-- they're weeps for help. A loose belt or a stopping working motor might be the perpetrators. One property owner stated how a consistent grinding sound ended up being a worn-out compressor, conserving them from a total breakdown by acting rapidly.

Typical Issues at a Glimpse

| Symptom | Likely Cause | Quick Repair |

|---|---|---|

| Warm Air | Low refrigerant or unclean filter | Replace filter, check refrigerant levels |

| Water Leaks | Obstructed drain line or frozen coils | Clear drain line, thaw coils |

| Unusual Noises | Loose parts or motor problems | Tighten up parts, inspect motor |

Is Your air conditioning Biking On and Off?

Short cycling is more than an annoyance; it can considerably lower your system's life expectancy. This could signal an oversized system or a thermostat problem. Have you noticed your system switching on and off like a flickering light? Do not disregard it. It's a subtle hint prompting you to call in the professionals before it becomes an expensive disaster.

- Dirty filters and coils cause air flow issues.

- Thermostat malfunctions cause irregular temperatures.

- Electrical problems can stop your air conditioner from beginning.

Necessary Tools for A/c Repair Work

Ever stood in front of a vast AC unit wondering which tool will open the secret? The right instruments can make all the distinction between a quick repair and an unlimited afternoon of aggravation. For example, a digital manifold gauge set isn't simply an expensive device; it's the investigator's magnifying glass worldwide of refrigerant pressure. Its precision helps determine leakages or imbalances that a casual glimpse may miss out on.

- Review of Bold City Heating & Air in Jacksonville FL by Melissa Amburgey: I have been with another company for five years and just got sick of the cost increases and inconsistent service. Cannon and Jonathan came out today to service my A/C and air handlers unit. They both communicated their concerns with me well and gave me comfort that they actually know what they're talking about. I am overall very pleased with my decision to continue biannual service with Bold City.

- Review of Bold City Heating & Air in Jacksonville FL by Jeff Kusch: great job… thanks !!

- Review of Bold City Heating & Air in Jacksonville FL by nick e: Very professional and customer service oriented

- Review of Bold City Heating & Air in Jacksonville FL by Jameson Lang: Cannon did an amazing job and was a hard worker

- Review of Bold City Heating & Air in Jacksonville FL by Althea Wunderler-Selby: Bold City has been our go to HVAC company for the last three years. They are responsive and professional and have bene able to accommodate last minute visits for emergency fixes. John has been our technician several times and is always helpful and patiently talks through any maintenance issues with us. When we had to replace our system we went with Bold City and were relieved to have a good financing option available.

- Review of Bold City Heating & Air in Jacksonville FL by Kristi Lamey: Bold City has been servicing my AC unit for the last few years. Justin, the service mgr was great and it was nice to see the same service mgr each time. He was professional and communicated the issues in simple terms I understood. As my unit got older, I finally decided it was time to get a new unit so I worked with Louis on a new copyright system. They had finance options available, which made the process easier. Seth and Tom did a great job doing the installation. They worked until it was finished, even though they ran into a few unforeseen issues. I really appreciate the entire team working together to get the unit installed and working in the same day.

- Review of Bold City Heating & Air in Jacksonville FL by Randy Miller: Jeremy came out the same day. He was very professional. He was able to diagnose the issue quickly and offered a much needed maintenance program and was not a pushy. We were very happy with the service and would recommend again.

When dealing with persistent or rusted components, a quality tubing cutter deserves its weight in gold. It slices through copper pipelines cleanly, avoiding damage that could result in pricey leaks. Have you ever tried to bend copper tubing by hand only to wind up with kinks? Avoiding this needs specialized flexing tools developed to maintain the pipeline's stability.

Tools That Experts Swear By

- Vacuum pump: Necessary for removing wetness and air from the system before charging refrigerant, making sure optimum efficiency.

- Drip detector: An essential for catching undetectable refrigerant leaks that can cause system ineffectiveness.

- Multimeter: Beyond measuring voltage, it's crucial for detecting electrical faults within the air conditioner's control system.

- Fin comb: A little yet magnificent tool that aligns bent condenser fins, improving airflow and performance.

Pro Tips for Using A/c Repair Work Tools

- Constantly verify your gauge readings against manufacturer specs; even skilled techs verify to prevent pricey misdiagnoses.

- When using a vacuum pump, ensure all valves and tubes are airtight; a minor leak can mess up the evacuation process.

- Tidy your fin comb regularly. Dust and grime can cause it to snag, damaging delicate fins even more.

In the heat of summer, a malfunctioning compressor or stopped up filter can seem like a ticking time bomb. However armed with the right tools and knowledge, the repair becomes less of an ordeal and more of a satisfying puzzle solved. Isn't it curious how a well-calibrated gauge or an easy leak detector can transform the entire result?

Step-by-Step Repair Process

Ever noticed how your air conditioning unit starts to sputter, hardly whispering the cool breeze it as soon as delivered? The first relocation is a comprehensive medical diagnosis-- because thinking only wastes time and resources. You may begin by inspecting the thermostat settings, however often the real perpetrator hides much deeper.

1. Preliminary Examination and Diagnostic

Begin by powering off the system to prevent shocks. Open the gain access to panels and aesthetically check for burnt wires, clogged up filters, or ice buildup. A common oversight is overlooking the condenser coils; dust and dirt here can choke efficiency. Use a multimeter to test electrical components and confirm if the compressor is getting power.

2. Identifying Refrigerant Issues

Does the unit blow warm air? That's often a sign of low refrigerant levels or leakages. Specialists utilize a manifold gauge set to measure pressure precisely. Keep in mind, overcharging or undercharging the system can trigger irreparable damage-- exact measurement is essential.

3. Cleaning Up and Element Replacement

Sometimes, a basic coil cleansing revives the system. Other times, it needs switching out capacitors, contactors, or fan motors. Replacing these parts involves cautious disassembly and reassembly; avoiding steps can result in additional breakdowns.

4. System Testing and Calibration

As soon as repairs are made, switch the system back on and observe its behavior. Procedure the temperature drop throughout the evaporator coil-- it must be approximately 15-20 ° F. If not, recalibrate the thermostat or examine for air flow blockages.

Specialist Tips

- Prevent running the compressor without refrigerant-- this burns out the motor rapidly.

- Use a UV dye to track down evasive leaks; they're often hidden in hard-to-reach areas.

- Never ever neglect the drain line-- clogs here can trigger water damage and system failure.

- Wear insulated gloves when handling capacitors; they maintain charge and can provide a nasty shock.

Defending Against Sudden Breakdowns

Have you ever questioned why your air conditioning unit sputters to a halt right at the peak of summertime? The truth is, ignoring routine upkeep frequently invites unforeseen failures. Dust, debris, and worn-out components wage a silent war inside your system. Preventive maintenance is the secret weapon-- catching small problems before they spiral out of control.

Specialist Tips for Keeping Your AC in Leading Forming

- Clean or change filters regular monthly: A clogged up filter chokes airflow, requiring the system to work overtime and accelerating wear.

- Check coil fins: Bent fins limit airway, just like a traffic jam in your cooling system. Use a fin comb to straighten them carefully.

- Check refrigerant levels: Low refrigerant can trigger the compressor to overheat, a precursor to costly repairs.

- Clear the condensate drain: Obstructions here can lead to water damage and mold development, a covert culprit behind sticking around odors.

- Analyze electrical connections: Loose wiring or rusty terminals often trigger periodic failures, a subtle caution sign.

When Was the Last Time You Listened to Your a/c?

That faint rattling or uncommon hum may appear unimportant, however it's a precursor to larger mechanical problems. One summertime, a client pointed out a soft buzzing noise. A fast evaluation revealed a loose fan blade-- simple to fix, yet left unattended, it could have shattered the motor. Moments like these underscore the worth of routine checks.

Quick Checklist for Seasonal Prep

| Action | Frequency | Why It Matters |

|---|---|---|

| Filter cleaning/replacement | Every thirty days | Maintains air flow and efficiency |

| Coil and fin assessment | Twice a year | Avoids air flow limitations |

| Refrigerant level check | Yearly | Makes sure proper cooling capability |

| Drain line clearing | Every 6 months | Avoids water damage and mold |

| Electrical system inspection | Each year | Avoids sudden shutdowns |

Pro Tip: Beyond the Basics

Did you understand that lightly lubing the fan motor bearings yearly can extend their life-span? It's a detail typically overlooked however vital. Also, shading your outside unit from direct sunlight can lower the compressor's work, discreetly boosting longevity. Remember, the health of your air conditioner is a reflection of the attention you offer it before it shouts for assistance.

Michael Bower Then & Now!

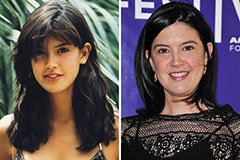

Michael Bower Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!